Prop - Tyranid Bonesword

Been wanting to make a larger weapon prop for a while, and also wanted to make something Tyranid themed. I couldn’t find any templates for this so it was a good opportunity to do it myself. I found a great 3d model here that appears to be based on the Space Marine 2 video game, and was a great model to work off.

I utilized Inkscape to trace around images of the model, including trying to capture the key markings on the sword. The final design is simpler than what the model was, including how aspects of the handle stick out quite wide, this dramatically simplified the work to put it together.

Materials used

- EVA foam 10mm, bulk of the sword

- Contact cement for sticking foam layers together

- Foam Clay for the organic parts of the handle

- Foam Sealer to seal foam ready for painting

- Primer good base and colour

- PVC Pipe for core

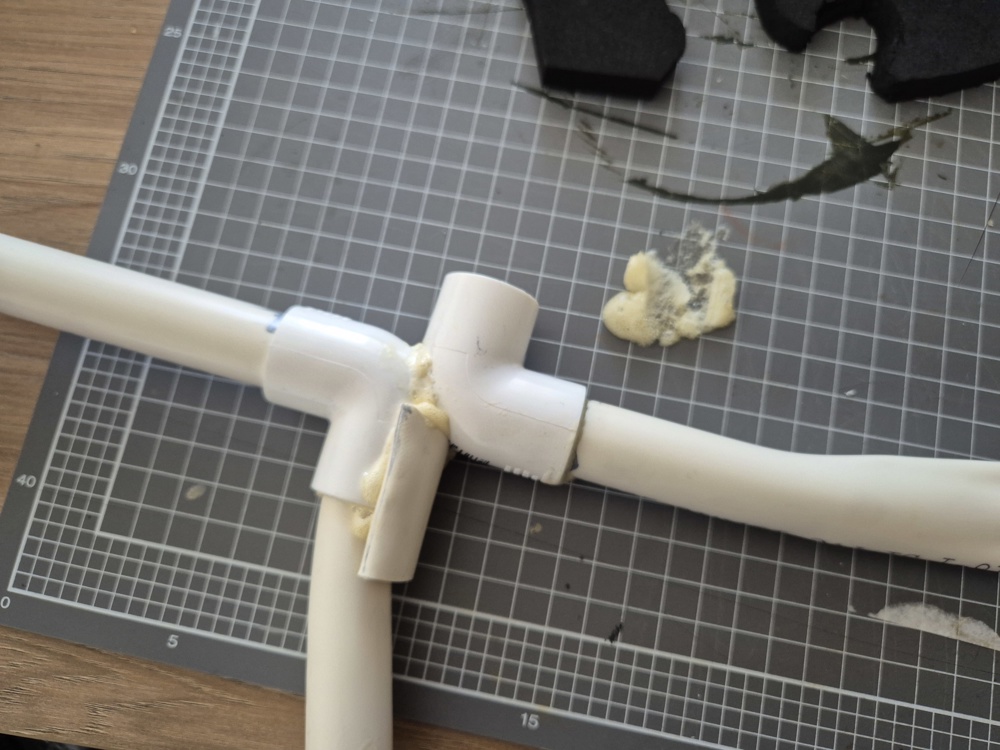

- PVC Connectors for extra support of the core

- Adhesive to glue pipe parts and counter-weight

Tools used

- Knife for cutting out foam

- Silver sharpy for tracing out template

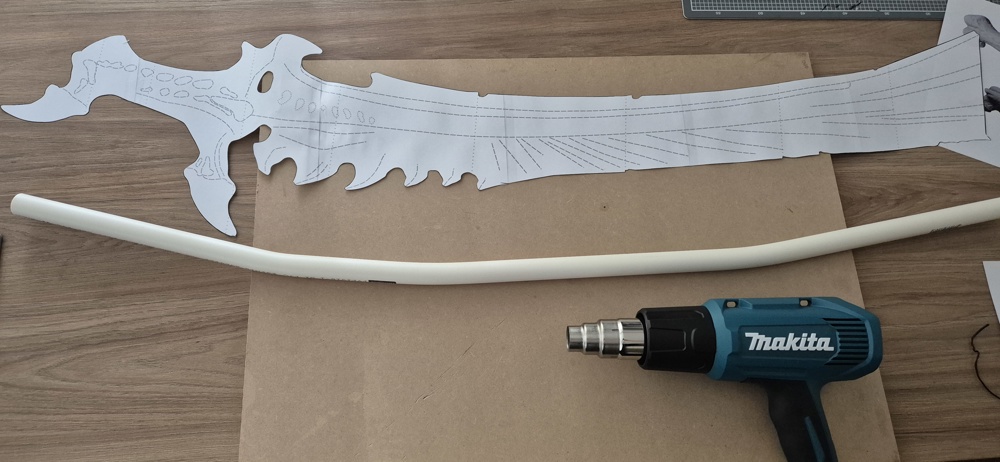

- Heat gun for sealing the foam

- Respirator when working with contact cement or heat-sealing the foam, very important!

- Safety glasses when working with contact cement, you don’t want that stuff in your eyes

- Ruler for general measuring

- Craft knife helpful for cutting paper

- Rotary tool for carving foam

The process

With the template cut out, I got a PVC pipe heated and bent into shape, roughly in the middle of the sword, providing strength for it.

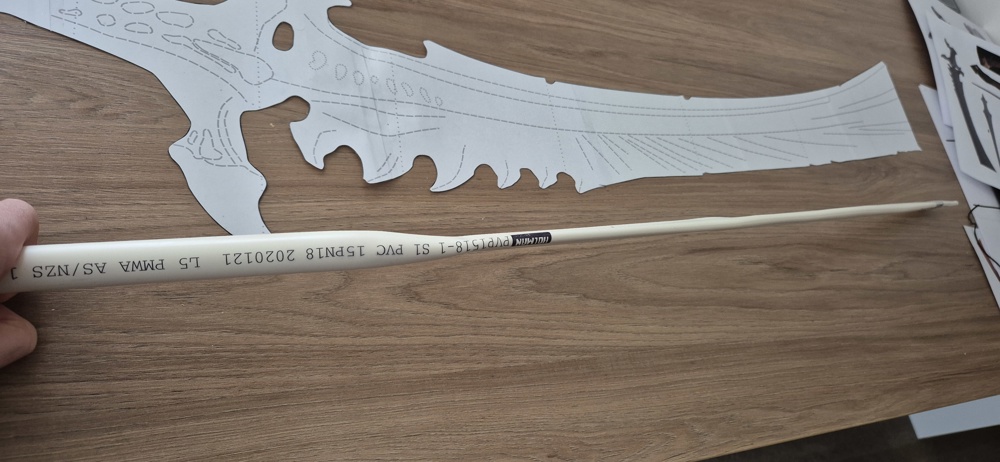

With a combination of heating and clamping I flattened most of the pipe. By being roughly the same thickness as the 10mm foam I only need to cut out space for it in the middle piece, and provides a better surface area to attach to.

Thought its easy to get the flat part of the pipe straight, also having the handle straight too was tricky, but heating the pipe allows for a bit of trial and error.

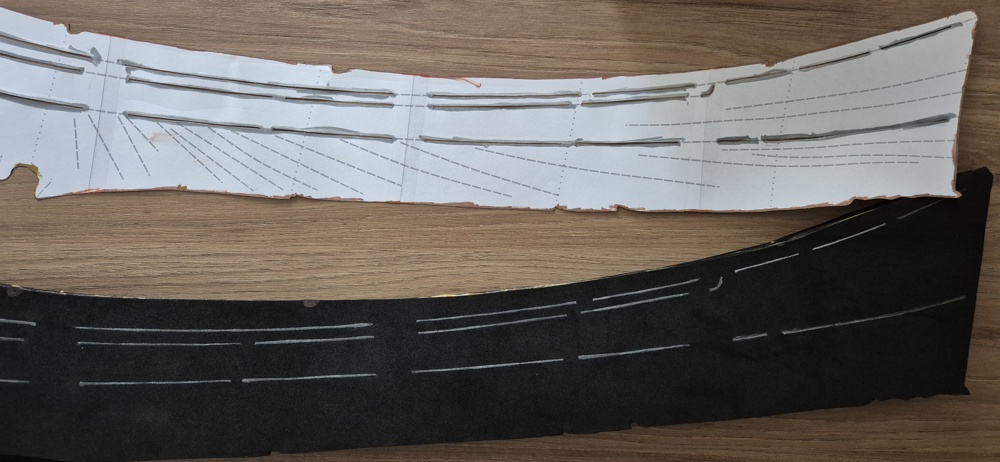

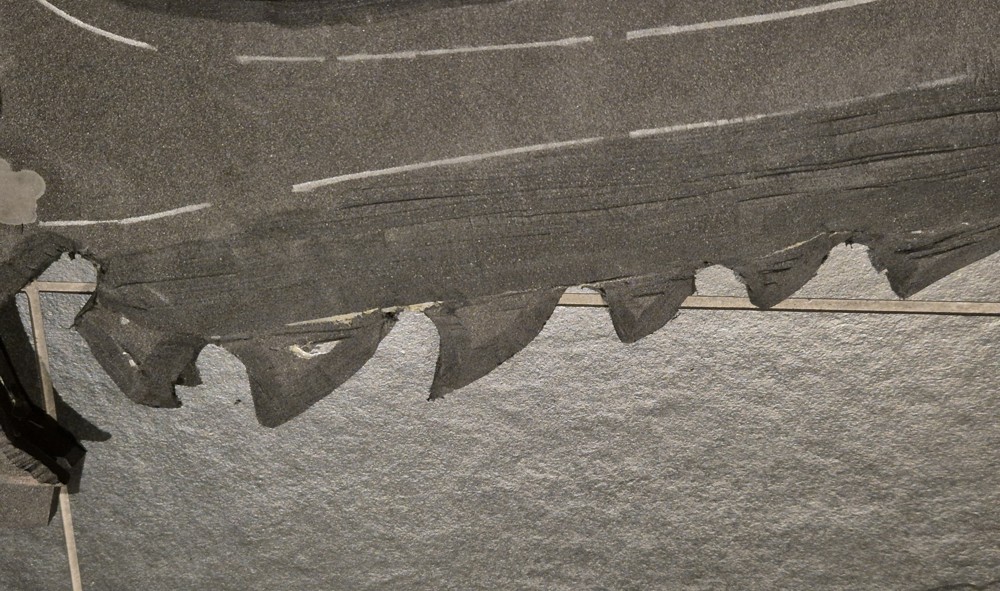

Cutting out the middle piece of foam, the other pieces are similar but this includes the jagged teeth at the bottom.

How the pipe looks on the middle piece, I did cut a bit of the flat end of the pipe so it can sit wholly inside the foam.

The outer pieces of foam cut out. Low density foam is being used here for a lighter weight.

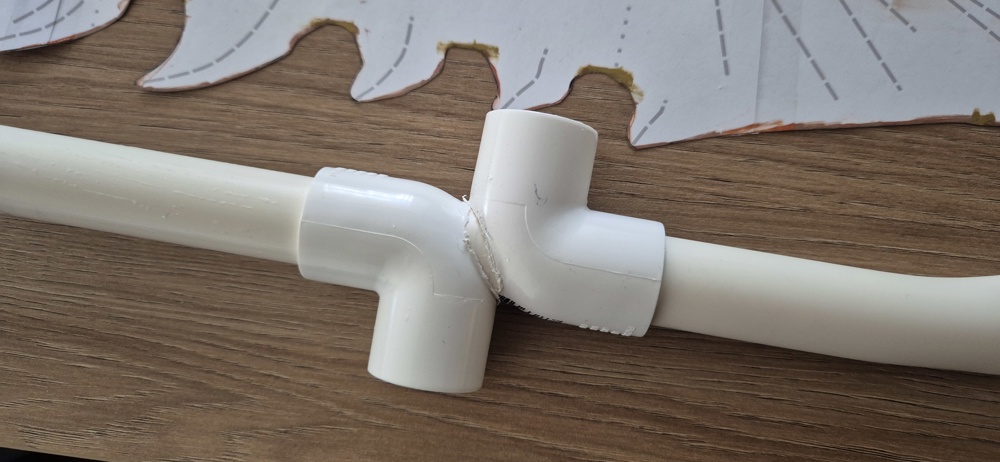

Was thinking of different ways to add support to the pipe and parts near the handle which could be used to hang the sword.

The first attempt would have worked if I was sticking with the original design where the handle guard sticks out, but because I leant towards a simpler and flatter look the second configuration was used.

This added extra support specifically to the hole that’s in the sword, easily being able to handle the weight of it if I wanted to mount it.

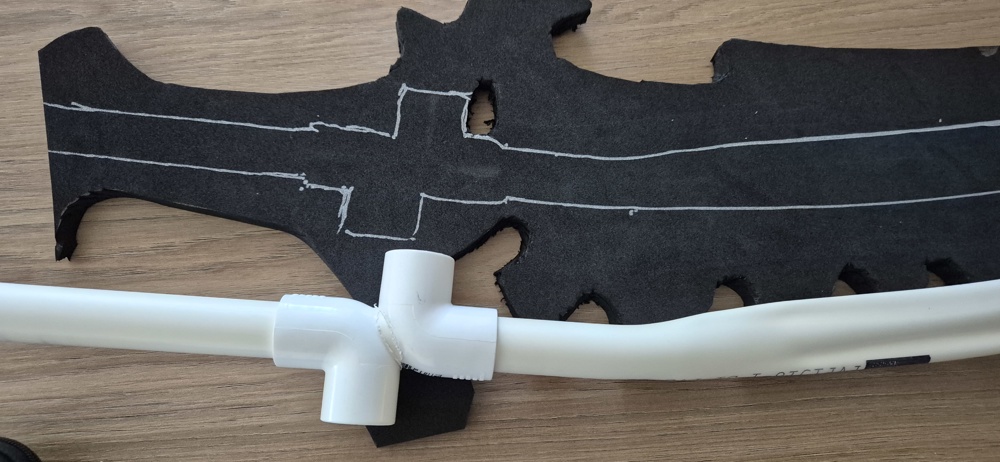

Tracing and cutting out a space for the pipe to sit in. Since the handle wasn’t flattened it will stick into the outer pieces a bit, which is why they are gouged out instead of being fully cut out.

Along with the support at the hole, I ended up adding more support to the lower part of the guard, again to help support the sword I was to hang it up.

I did end up cutting out more of the outer pieces so the pipe can git snug, but this will be covered in foam clay so wouldn’t be visible in the end.

It’s hard to get pictures when the process has to be quick, but here I started gluing the foam and pipe together. I started with contact cement for the outer and middle layer.

Then using hot glue added the pipe. The final outer layer was a combo of hot glue and contact cement, being weighed down with various things to help with adhesion.

It didn’t have to be perfect, but added a heavy bolt right in the handle to help balance the sword. It’s still a bit balanced more towards the blade, but far better than without it.

A few pictures of the pieces glued together, now we can start trimming and shaping the sword a bit.

The design of the sword had a lot of detail, including larger gouges which is what I roughly traced out on the foam. Again since I was going for a simpler look, I focused more on the obvious parts.

This meant keeping part of the blade flat, with the top having a sharp angle, and the bottom (the main part of the blade) having a more shallow angle.

The rough cuts around the edges, this will be dremelled and smoothed out later.

The final piece with the edges cut.

First look at foam clay around the handle, hidding and filling in the parts cut out for the pipe to fit in.

Also the first pass of dremelling to smooth out the edges more and hide the rought cuts.

Along with smoothing out the edges a bit, I also added lines and striations to add detail to the piece, otherwise it would be quite flat when I want it to look almost organic.

More pictures of the applied foam clay and the bone horns to the guard and handle. More foam clay was used around those bits to bulk them out.

The final piece with all the foam there and gouges and roughing up having been applied. Seeing a bit of the pipe is fine, the flexbond layers will cover this.

A close up of the piece after the flexbond has been applied and set. Also did stiffling of the flexbond onto the sword in an effort to add more texture to it.

I think it was pretty minor the impact that had on the final result, there could be more effective ways to do it but I’m still happy with the result.

With the flexbond set it was time for the painting. A dark scarlet red spray can was used for this. Missed some areas a bit such as the hole (as that was how it was hanged when I sprayed), and the grooves between the teeth, but these were touched up later.

Overall I wanted it quite a dark red, but to have clearer definition of the grooves and edges so they can be emphaised a bit.

I applied a few black washes over the whole sword and used a bit of cardboard to wipe away the wash, this allowed the wash to remain in the recesses while everything was removed.

When it dried the black was more grey and didn’t look like I was hoping. I ended up using slightly thinned black and filling in all the gouges with a smaller paint brush, though a bit of work it looked much better and defined.

To help highlight the edges I used a mix of red and a little bit of black (as it was quite strong), then using the side of a small brush run it over the whole sword, focussing on the main edges and even the main body.

The picture above is just after the paint was applied, so looks a bit brighted before it dried it darker, which was still lighter than the base and shade colours.

Then we get the final result! A matte spray was used to help protect it.

Very happy with the final result, and glad I pivoted away from trying to match the 3d model exactly and used it as guide for something that still looks cool but was far easier to make.

If I were to do this again I don’t think that I would change much about the process or the finished piece, perhaps more gouges and slightly better counter weight.

Fortunatelly the sword needs to be organic and messy, so things that would standout on straight/flat pieces look like they are part of the sword.

Learnings

- Consider oil paints for the shading, they take far longer to dry but may result in a better look.

- Perhaps even more gouges, with mixture of small/narrow to larger/wider

- Whether with flexbond or something else, having more defined stiffiling to add to the texture.

- The spray paint will highlight this easily, but couldn’t notice them much with the amount of stiffiling I did.